From design to finished product: the journey of underwear production

- Share

- Issue Time

- Jun 14,2025

Summary

In the underwear industry, consumers usually only see the final product, but from design to completion, each piece of underwear goes through a complex and sophisticated production process.

From design to finished product: the journey of underwear production

1. Design: The starting point of creativity

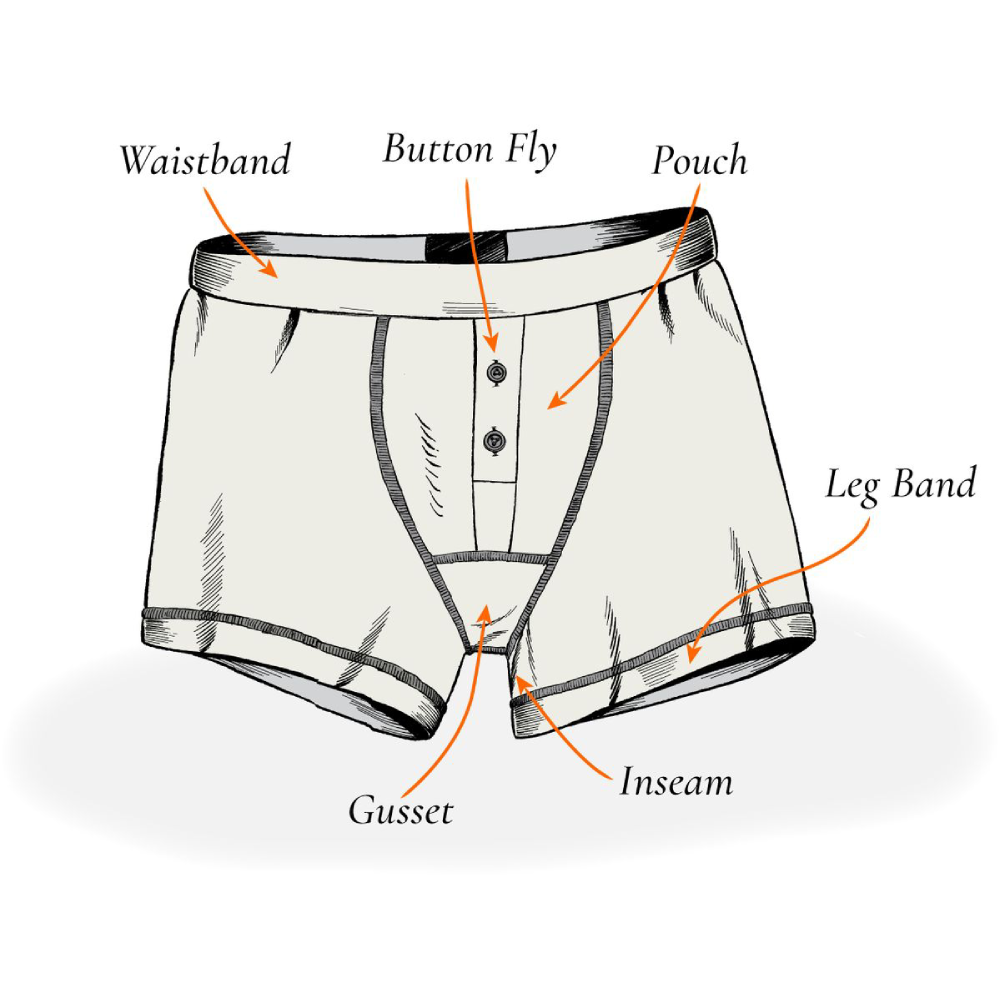

The birth of every piece of underwear begins with design. Designers create underwear styles that meet the aesthetic tastes of modern consumers based on market demand, fashion trends, functional requirements, and comfort. Designers must not only consider the beauty of the style, but also pay attention to details such as comfort and wearing experience to ensure that each piece of underwear can meet the needs of different consumers.

2. Fabric selection: Comfort and quality are equally important

An excellent bra cannot be separated from high-quality fabrics. Fashion Oxygen will provide a variety of fabric options according to the needs of designers, including cotton, lace, silk, etc. Each fabric is strictly screened to ensure that its breathability, softness, durability and other aspects meet the standards. High-quality fabrics are the guarantee of the comfort of the bra and the core of its wearing experience.

3. Sample production: fine craftsmanship

After the design and fabric selection are completed, Fashion Oxygen will start making underwear samples. At this stage, the craftsman will be precise to every detail to ensure that each sample can perfectly present the designer's creativity. The production of samples requires not only superb technology, but also a deep understanding of design and fabrics. Each sample will undergo rigorous testing to ensure that it is not only flawless in appearance, but also extremely comfortable to wear.

4. Mass production: accurate and efficient

After the sample passes the review, it enters the mass production stage. In this link, Fashion Oxygen will use an efficient production line to ensure that each piece of underwear can be accurately manufactured according to the design requirements. The production mode combining automation and manual labor not only improves production efficiency, but also ensures that the quality of each piece of underwear can be strictly controlled. Every seam and every detail is strictly checked.

5. Quality inspection: ensuring perfect quality

After production, the underwear will enter the quality inspection stage. Fashion Oxygen will conduct multiple inspections on each batch of underwear, including size, stitching, elasticity, durability of fabrics, etc. Only underwear that has passed strict inspection can enter the market, ensuring that every piece of underwear worn by consumers is of high quality.

6. Packaging and delivery: providing customers with a high-quality experience

Finally, the underwear will be carefully packaged and prepared for delivery to major retailers or directly to consumers. Fashion Oxygen also pays attention to details in packaging to ensure that every piece of underwear can be delivered to customers in the best condition, allowing consumers to experience high-quality service

7. Summary: Every step of underwear production cannot be ignored

From design to finished product, Fashion Oxygen has devoted a lot of effort and energy. The birth of each underwear is the joint effort of countless craftsmen, designers, quality inspectors and production personnel. It is this spirit of excellence that has achieved the comfort and high quality of underwear, and also allowed consumers to experience the perfect combination of fashion and comfort.